Today, while reviewing the installation of a low-temperature warehouse at work, I delved into researching various types of expansion valves to determine the most suitable option. I sought to understand the functionality and operating principles behind these valves, as well as explore the different types and their distinct characteristics.

- Function of Expansion Valves

- Principle of Operation of Expansion Valves

- Types of Expansion Valves

1. Function of Expansion Valves

The expansion valve is a critical component in refrigeration and air conditioning systems, responsible for regulating the flow of compressed refrigerant to maintain balance within the refrigeration system. This valve functions by controlling the flow rate of refrigerant within the system, allowing it to adjust refrigerant pressure and temperature to accommodate fluctuations in the cooling load. By managing the flow of refrigerant, it facilitates the system’s ability to adapt to changes in refrigeration demands, ensuring efficient operation

2. Principle of Operation of Expansion Valves

2-1. Throttling within the expansion valve

(1) When a fluid passes through a narrow passage like a nozzle or an orifice, pressure decreases without any exchange of heat or work with the surroundings. This phenomenon is known as throttling.

(2) Throttling of a fluid during flow causes an increase in fluid friction and turbulence, resulting in pressure loss.

(3) In the case of a liquid, when throttling occurs and the pressure drops below the liquid’s saturation pressure, some of the liquid evaporates. This evaporation absorbs heat from the liquid itself, causing a decrease in the liquid’s temperature. As throttling is an adiabatic expansion process, there is no change in enthalpy before and after throttling (isoenthalpic process).

2-2. Flow control of expansion valve

(1) When the expansion valve is opened too much

- an excessive amount of refrigerant flows, increasing the risk of liquid compression.

- As the ejection speed of the refrigerant decreases, the evaporation pressure increases.

- Evaporation temperature rises.

(2) When the expansion valve is opened too little

- The increased refrigerant discharge velocity reduces the evaporating pressure, leading to a decrease in evaporating temperature

- Compression ratio increases.

- With reduced refrigerant circulation, the compressor intakes superheated vapor, causing the compressor to overheat

- Volumetric efficiency decreases.

- Refrigeration capacity decreases.

- Leads to lubricant degradation and carbonization.

3. Types of Expansion Valves

3-1. Manual expansion valve

A method of controlling the flow rate of refrigerant manually by turning the valve handle with a high degree of skill. Let’s not even look into this anymore.

3-2. automatic expansion valve

It is an expansion valve that can automatically adjust the flow rate according to the state of the refrigerant in the evaporator. It is divided into temperature type, static pressure type, and float type.

Temperature-sensing automatic expansion valve

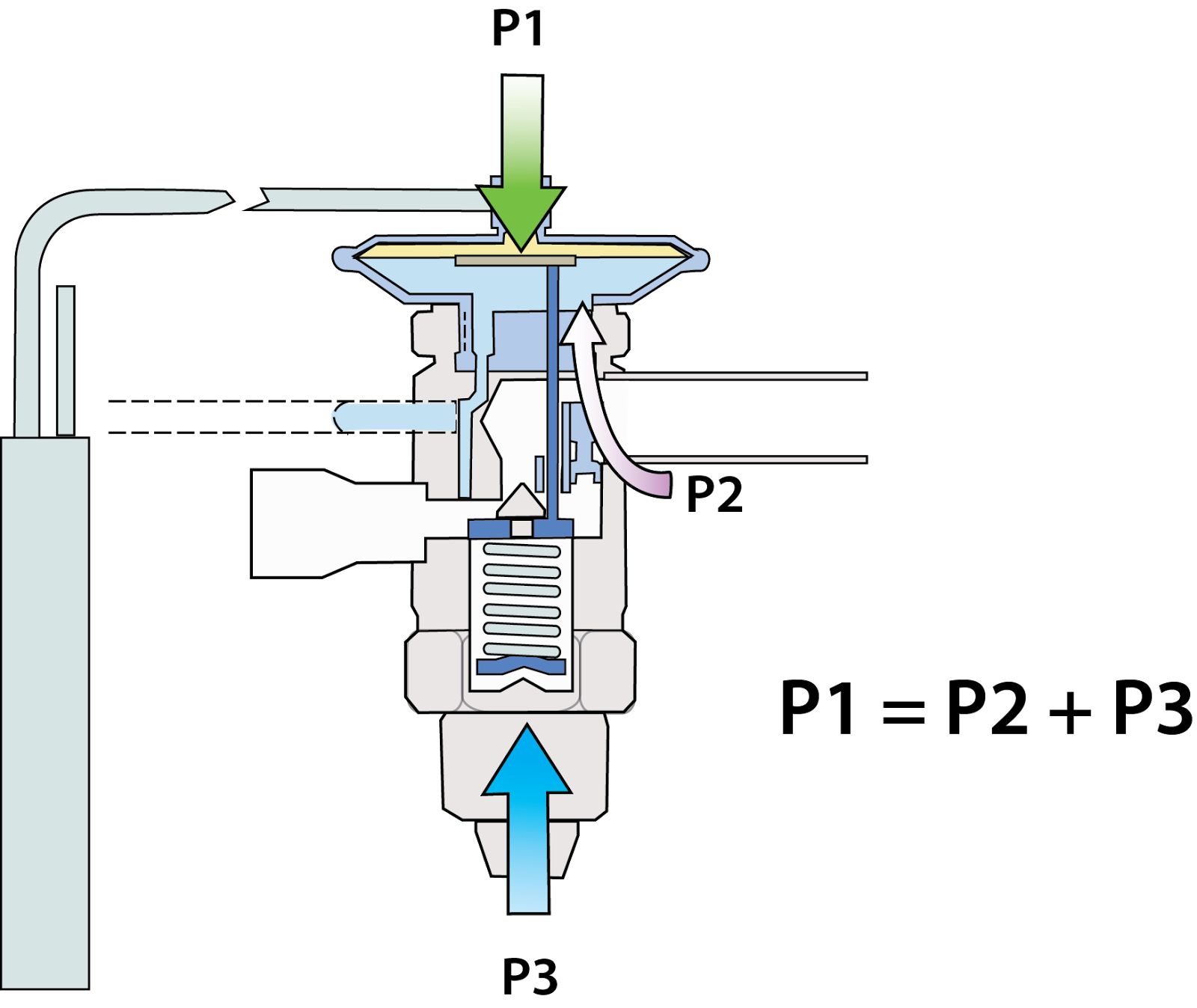

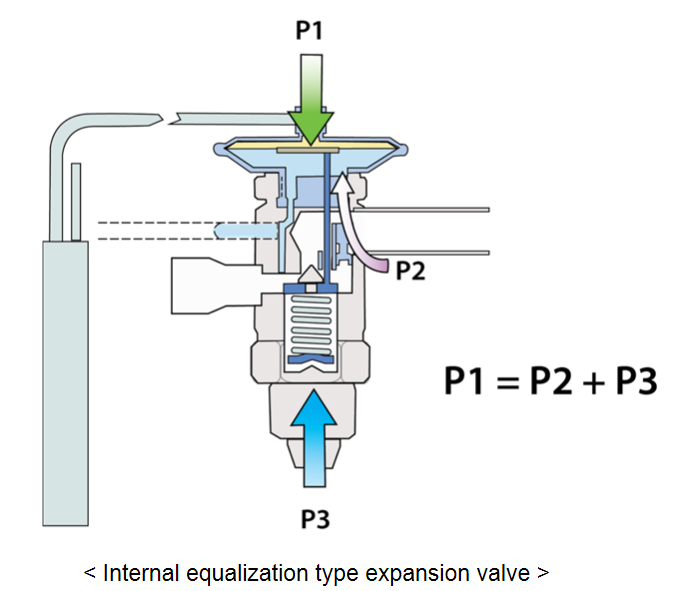

- The most commonly used method for controlling refrigerant flow in small refrigeration and air conditioning units is based on evaporator superheat control.

- This method adjusts the refrigerant flow by regulating the valve opening concerning the superheat at the evaporator outlet. When the superheat increases, the valve opens, and when the superheat decreases, the valve closes to control the refrigerant flow

- Internal equalization Type: Used when pressure drops are low.

- External equalization Type: Employed when pressure drops are high.

(2) Constant pressure automatic expansion valve

- This valve maintains a constant evaporation pressure within the evaporator, thereby ensuring a consistent evaporating temperature.

- The valve closes when the pressure inside the evaporator rises due to pressurizing the top of the valve, and it opens when the evaporation pressure decreases.

- It’s utilized when it’s not necessary to control the refrigerant quantity based on the load, typically in cases of minimal fluctuations in refrigeration load or for preventing freezing in cooling water, brine, and similar systems.

(3) Float expansion valve

-. High pressure side float expansion valve

- A float is installed on the liquid surface of the high-pressure side separator to maintain a consistent level of the condenser or the liquid surface in the separator, depending on the condensing load.

- When the liquid surface in the high-pressure side separator rises, the float valve lifts, allowing refrigerant supply to the evaporator. Conversely, when the liquid surface decreases, the float valve descends, cutting off the refrigerant supply.

- As it operates based on the liquid surface of the high-pressure side separator, adjusting the refrigerant quantity according to fluctuations in the evaporating load is not feasible.

-. Low pressure side float expansion valve

- This is installed on the liquid surface within the low-pressure evaporator and is used in constant-level evaporators.

- It ensures simple control of refrigerant flow and maintains a consistent liquid surface on the low-pressure side of the evaporator regardless of load fluctuations.

3-3. capillary tube

Expansion devices can be replaced by a kind of expansion structure utilizing pressure loss of fluids passing through small passages, typically thin and long tubes with an inner diameter of approximately 0.6 to 2 mm. However, it’s not suitable for devices with significant load fluctuations and can significantly impact device performance if the refrigerant charge in the device is insufficient.

- It is used in small refrigeration units utilizing Freon refrigerants, such as household refrigerators, room air conditioners, and showcases.

- Due to pressure loss through capillary tubes, flash gas is generated, reducing the refrigerant temperature to the evaporation temperature.

- The greater the pressure drop caused by the capillary tube, the thinner the diameter and the longer the length, the stronger the pressure drop.

- When the compressor stops, equilibrium is achieved between the high-pressure and low-pressure sides, making the next startup easier.

- There’s a risk of moisture or foreign substance freezing and obstructing, hence the need for a dryer (dehumidifier) and a strainer.

- It has a simple structure, resulting in fewer breakdowns.

※ Choking Flow: When liquid refrigerant flows through a capillary tube, which is a type of expansion valve, a portion of the liquid refrigerant turns into vapor. As the capillary tube extends infinitely, the amount of vapor generation increases, leading to an increase in velocity until it reaches the speed of sound. This phenomenon is called choking flow. In the supersonic choking flow, the flow rate no longer increases but maintains a constant flow. When the capillary tube reaches supersonic choking flow, system operation stabilizes.

Today we learned about expansion valves. Although the expansion valves listed above are all assumed to sense temperature or pressure mechanically, there are also electronic expansion valves that use sensors and electronic control devices to detect accurate temperature and pressure and control the refrigerant flow rate. Rather, most automobile cooling systems or air conditioning systems have electronic expansion valves installed.

After all, expansion valves play a vital role within the system and must be installed and maintained properly. Improper operation of the expansion valve can reduce the efficiency of the cooling system and lead to system failure. Therefore, it is important to maintain it carefully and adjust it appropriately to optimize system performance.